ClearFox® SBR

Biological Process Technology

Sequential Batch Reactor

- Flexible and Scalable

- High Effluent Quality

- Low Maintenance

- EN 12566-3 Certified

Gallery

Description

ClearFox® SBR systems offer a sustainable solution for biological wastewater treatment in municipal and industrial applications of up to 5000 PE (population equivalents). The systems are based on the proven SBR process (Sequencing Batch Reactor), which, thanks to our intelligent control technology, ensures high treatment performance with minimal maintenance. ClearFox supplies both fully pre-assembled SBR systems in concrete tanks as well as flexible retrofit kits that can be integrated into existing concrete or PE tanks. This makes the systems ideal for both new installations and the modernization of existing treatment plants. Our engineering specialists offer both single- and multi-chamber SBR systems, tailored to the customer’s individual needs.

How It Works

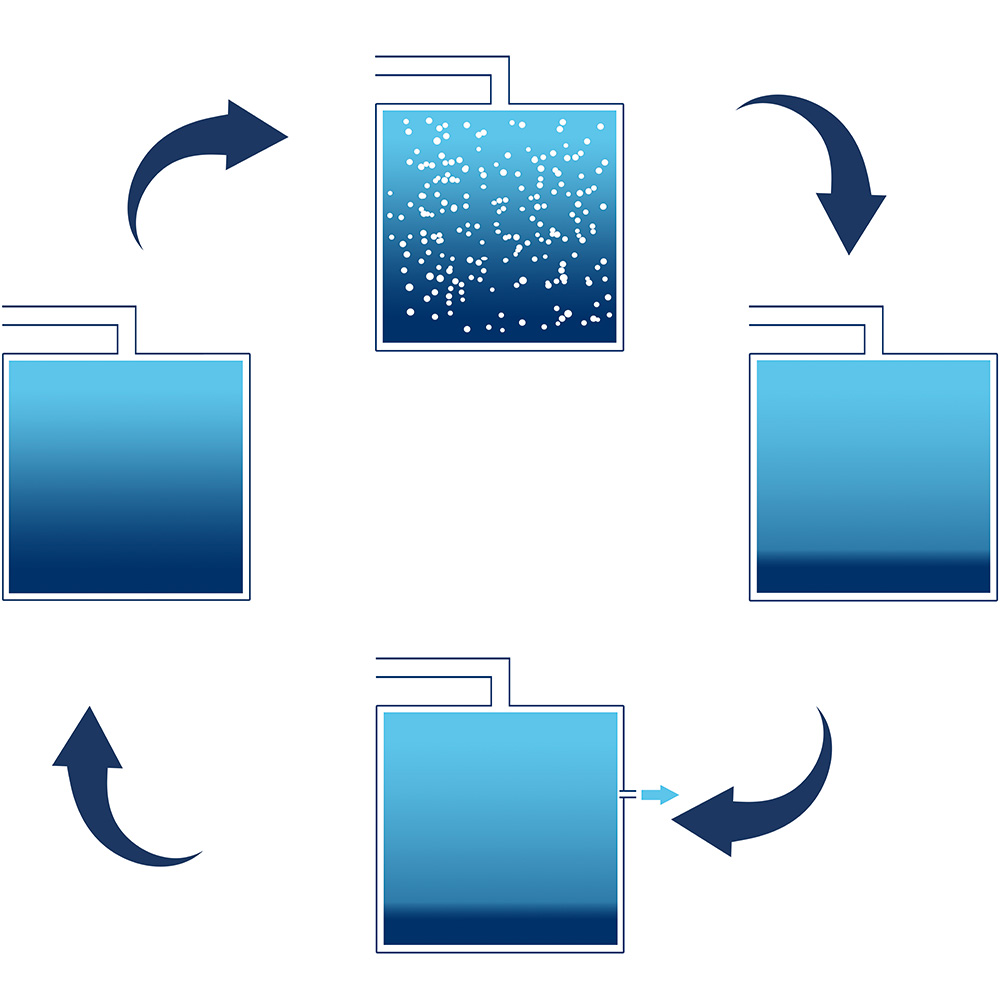

SBR process in a single-chamber tank

Filling Phase: Wastewater flows into the biological reactor. An automatic level sensor monitors the inflow and adjusts the cycle times accordingly.

Aeration and Treatment Phase: In the SBR reactor, the wastewater is aerated using fine-bubble membrane diffusers. This supplies oxygen to the microorganisms that enables biological treatment. Aerated and non-aerated phases alternate to support nitrification and denitrification, fully controlled by intelligent control software.

Settling Phase: After the aeration phase, the activated sludge settles to the bottom of the biological reactor and a clear water zone forms in the upper part of the tank.

Clear Water Discharge: After settling, compressed air flushes the air-lift pumps to clean and remove any suspended solids. The air-lift pump then discharges the clarified water from the reactor.

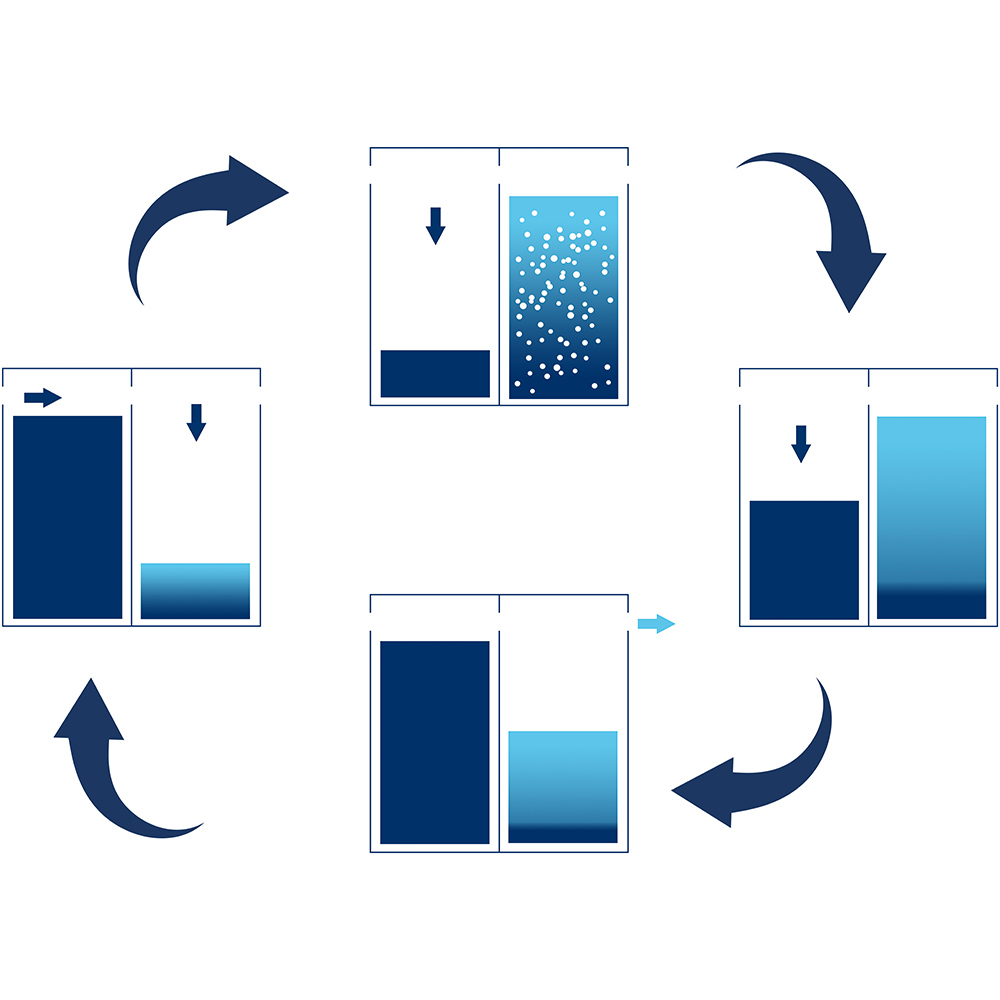

SBR process in a multi-chamber tank

Filling Phase: Wastewater flows into the first chamber, where coarse solids settle to the bottom via sedimentation. Water from the primary chamber is then transferred into the biological reactor using an air-lift pump.

Aeration and Treatment Phase: In the SBR reactor, the wastewater is aerated using fine-bubble membrane diffusers. This supplies oxygen to the microorganisms that enables biological treatment. Aerated and non-aerated phases alternate to support nitrification and denitrification, fully controlled by intelligent control software.

Settling Phase: After the aeration phase, the activated sludge settles to the bottom of the biological reactor and a clear water zone forms in the upper part of the tank.

Clear Water Discharge: After settling, an air-lift pump discharges the clarified water from the reactor. The system transfers the settled activated sludge back to the first chamber and the process starts again.

PPU manufactures the ClearFox® SBR using a precise production process that meets the highest quality standards and is ISO 9001 and 14001 certified. The team employs state-of-the-art technology and durable materials to ensure reliable, low-maintenance performance. Each system is carefully planned and designed to meet individual requirements, ensuring a tailored solution for every application.

Advantages

- Reliable Operation, no Risk

The ClearFox® SBR system operates fully automatically. There are no mechanical or electrical parts in contact with the wastewater, significantly reducing the risk of malfunctions. The integrated control panel includes a wide range of alarm options to quickly detect and respond to any issues. Systems are designed in accordance with DIN EN 12566-3 or ATV-DVWK/DWA M-210, ensuring trouble-free operation for our clients.

- Smart, Efficient, Hassle-Free

Our system intelligently adapts to changing inflow volumes. It reliably handles both underload and overload without compromising treatment performance. In underload conditions, the system activates a special holiday mode, reducing cycle frequency and significantly lowering energy consumption. Also, we use clog-free, maintenance-free airlift-pumps for minimal energy use. This makes it ideal for seasonal use such as in holiday homes.

- Low CapEx and OpEx

For wastewater treatment projects (schools, hotels, residential, etc) the SBR equipment represents a highly efficient process technology. Market leading effluent standards combined with the lowest OpEx and CapEx makes the ClearFox® SBR an excellent choice for efficient wastewater treatment.

Videos

Downloads

Reference Projects

FAQs

1. What is the ClearFox® SBR Standard Kit?

2. What are the key advantages of the ClearFox® SBR Standard system?

- Cost-Effective: Offers low capital (CAPEX) and operational expenditures (OPEX).

- Flexible Installation: Suitable for tanks of any shape, material, and can be installed above or below ground.

- High Efficiency: Achieves market-leading effluent standards with low energy consumption.

- Automatic Operation: Fully automated with integrated energy-saving modes that adapt to actual sewage volumes.

- Low Maintenance: Utilizes clog-free and maintenance-free airlift pumps, with no electrical or rotating parts in the wastewater.

- Certified Quality: Designed according to DIN EN 12566-3 standards and CE certified.

3. How does the SBR process work in wastewater treatment?

4. Can the ClearFox® SBR Standard system handle varying wastewater volumes?

Yes, the system features an integrated energy-saving mode that automatically adjusts to actual sewage volumes, optimizing energy usage and maintaining treatment efficiency.

5. What maintenance requirements does the ClearFox® SBR Standard system have?

6. Is the ClearFox® SBR Standard system certified?

Yes, the system is designed according to DIN EN 12566-3 standards and carries CE certification, ensuring compliance with European quality and safety regulations.