ClearFox® Screw Screen

Solids Separation

Compact Mechanical Pre-Treatment

- Self Cleaning

- No Clogging

- Low Maintenance

- Flexible Design

Gallery

Description

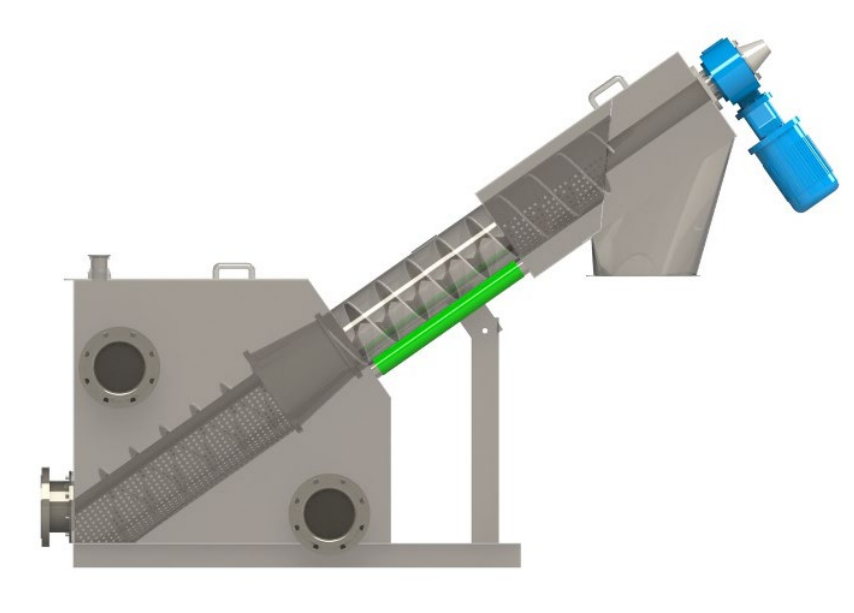

The ClearFox® CSS Screw Screen is a compact solution for screening municipal and industrial wastewater. It reliably separates coarse solids such as fibers, plastic particles, and organic residues from the wastewater stream. It is used as mechanical pre-treatment to remove floating, settling, and suspended solids. Clearfox® screw screens reduce the volume of solids by up to 35% and are suitable for flow rates of up to 1,000 m³/h. The unit is CE marked and equipped with low-wear motors, ensuring high reliability and minimal maintenance for trouble free operation.

How It Works

- Wastewater first enters the inlet section of the screw screen, where it passes through a fine-mesh screen that retains coarse solids. These solids accumulate on the screen surface, while the pre-treated water continues to the next treatment stage. Once a sufficient amount of solids has collected, the screen surface is cleaned by robust stainless steel screw flights equipped with wear-resistant brushes.(1)

- The spiral screw then transports the retained material toward the discharge. Along the way, the material is dewatered and excess water flows to the next treatment stage. The spiral becomes narrower towards the end of the screw which causes the separated solids to be compressed.(2)

- Finally, they are discharged in a compact form into a downstream collection container or plastic bags. The entire process operates fully automatically, ensuring reliable and low-maintenance preliminary treatment of the wastewater.(3)

Inlet Channel

Inclined Lamella Package

Sludge Hopper

The system operates fully automatically, and all relevant parameters can be adjusted via a control display. Optional remote monitoring with remote access allows real-time status checks and convenient adjustments from a distance.

ClearFox® Compact Screen Unit (CSU) - Extension of the ClearFox® Screw Screen

The ClearFox® CSU is an extension of the ClearFox® Screw Screen. It is a fully automatic system to remove fats, oils, grease, sand, grit and inorganics from wastewater. Designed for municipal and industrial applications, the ClearFox® CSU ensures effective pre-treatment to protect downstream biological processes, pumps or hoses. When passing through the compact unit, solids are screened, compacted, dewatered, and sand and grease are removed.

The wastewater flows into the compact plant and the solids are separated by a screw screen. In a second step, sedimentation and the removal of sand and grit take place. Finally, oils and greases are separated by a floating scraper.

The machine consists of the following parts:

- Screw Screen

- Grease Trap

- Sand Trap

- Rake

- Blower

- Compressor

Advantages

- Low Maintenance

Minimal maintenance requirements

The screw screen operates without internal bearings and is equipped with durable, wear-resistant brushes. This keeps maintenance to a minimum and increases overall reliability. Optional remote monitoring with integrated access can also be implemented.

- Coarse Materials Handling

Reliable operation even with fibrous materials

The shaftless spiral prevents blockages and ensures trouble-free operation, even when handling fibrous substances such as textiles or hair. The screw screen operates reliably, even with fluctuating inflow volumes.

- Integrated Dewatering

Reduced volume, lower disposal costs

Thanks to integrated dewatering and compaction, the volume of retained material is reduced by up to 35%. This minimizes disposal frequency and lowers operating costs for the plant operator.

- Flexible Design

Flexible configuration for various applications

The Clearfox® screw screen is available in different sizes and models and can be tailored to your specific requirements. Depending on particle size and flow rate, we will find the ideal configuration for your application. Available with punched hole or wedge wire screens (0.25 to 10 mm) and flexible installation options in channel, container, or vertical pump station

Videos

Specifications

| ½ Lamella clarifier module | |

|---|---|

| Dimensions: (l, w, h) / ½ module (m) | 1,35 x 2,10 x 2,57 |

| Footprint: (m²) | 2,8 |

| max. transport weight: (kg) | 400 empty |

| Max. operating weight: (kg) | 8000 filled with water |

| Max. Flow rate | 9 m³/hr |

Downloads

Reference Projects

FAQs

1. What is a screw screen and how does it work?

A screw screen is a mechanical solids separation system that removes coarse materials from wastewater. A screen basket retains the solids while the screw collects them, cleans them automatically, transports them upwards, dewaters them and compresses them. The process is continuous and low-maintenance.

2. For what applications is a screw screen suitable?

It is suitable for:

- Municipal wastewater treatment plants (inlet screening stage)

- Industrial pre-treatment (e.g. food, textiles, paper, plastic recycling)

- Pumping stations and stormwater overflows

Containerised wastewater treatment plants with upstream coarse material discharge

3. What screen sizes are available?

The sieve mesh width can be customised for each project:

- Wedge wire: 0.25-3 mm

- Round hole: 2-10 mm

This allows the retention to be adapted to the requirements – from fine materials to coarse fibres.

4. How does the screw screen prevent clogging?

Thanks to their shaftless screw guide, rotating brushes and self-cleaning screen surface, clogging is virtually impossible – even with fibre-rich media.

5. What throughput rates can be achieved?

Depending on the model, up to 963 m³/h (268 l/s) can be processed. The capacity depends on:

- Screen type and width

- solids concentration

medium viscosity

6. How much solids concentration can be processed?

The systems are designed for concentrations of up to 500 mg/l (0.05 %) – typical for municipal and industrial inlet wastewater.

7. How easy is the integration into existing systems?

Thanks to standardised DN flange connections (DN150-DN400), flexible inlet/outlet position (left/right) and compact dimensions, retrofitting in existing shafts or systems is no problem.

8. What energy supply is required?

The motors require 380-480 V at 50/60 Hz, with outputs between 0.75 and 1.1 kW. An ATEX motor for potentially explosive atmospheres is available as an option.

9. How does the operation work? Does someone have to be on site?

The system operates fully automatically. Remote monitoring via GSM module (optional) is possible. The cleaning cycles of the sieves start automatically via level detection or timer.

10. How much maintenance is required?

Very little. The self-cleaning brush mechanism reduces manual cleaning to a minimum. Regular visual inspections and occasional replacement of brushes are sufficient.

11. What is the lifespan of a screw screen?

With proper maintenance, the service life of ClearFox® screw screens is often over 15 years in practice – even in continuous use.

12. How big and heavy is a screw screen?

The dimensions vary depending on the model. For example:

- CSS 250: 2.98 × 0.48 × 2.10 m

- CSS 960: 3.46 × 0.72 × 2.50 m

The weight is between 300-650 kg. The systems can be moved by forklift truck or crane.

13. Is a licence required for the screw screen?

Usually, it is part of the overall approval of the wastewater treatment plant. An independent approval is not necessary, provided that CE conformity and DIBt approval of the overall system exist.

14. Why should you choose a ClearFox® screw screen?

- Robust technology ‘Made in Germany’

- Low maintenance thanks to self-cleaning elements

- Flexibility in size, installation, customisation (e.g. sieve bars, accessories)

- Sustainable and economical operation