ClearFox® QuickOne

Domestic Sewage Treatment Plant

Tagline

- No Noise

- No Odour

- Low Maintenance

- EN 12566-3 Certified

Gallery

Description

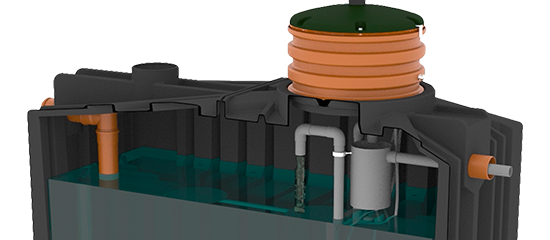

The ClearFox® QuickOne+ is a fully pre-assembled SBR domestic sewage treatment plant, manufactured in Germany by PPU Umwelttechnik GmbH. It is suitable for new developments, or as an upgrade to a septic tank system for houses, schools, restaurants and other commercial or domestic applications. Complete systems available for up to 24PE, and equipment kits for local tank installation for bigger populations. With add on modules for phosphorus removal and disinfection, it can be installed in sensitive areas. It is also tested and proven to have desludging intervals of more then 1 year. Thanks to an integrated pressure sensor, the QuickOne can independently adjust the aeration times. At higher inflow peaks, the system increases oxygen to enhance performance. If the inflow is low, the system switches to standby mode.

How It Works

1. Filling

The wastewater flows into the ClearFox® QuickOne. The automatic fill level measurement recognises when wastewater flows into the domestic sewage treatment plant. The cycles are then adjusted accordingly

2. Cleaning and Aeration

The system injects air into the wastewater via perforated discs at the bottom of the tank. During the aeration process, the microorganisms consume the carbon and nitrogen in the wastewater. The duration of aeration is adapted to each individual type of wastewater. The more contaminated the wastewater, the longer the aeration phase. This also ensures uniform mixing of the wastewater. The process is fully biological and does not require the addition of chemicals.

3. Settling

From the buffer tank, the wastewater flows onto a mechanical tipper tray. This fills continuously with wastewater until it tilts due to the increasing weight on one side. Thus, it distributes wastewater equally over the perforated distribution tray. All parts of the flow control and distribution system are made of durable and corrosion-free HDPE. Via the perforated tray, the wastewater flows with even distribution into the biological reactor below. This guarantees stable operation without overloading, and ensures the effluent quality is consistent.

4. Flushing

There are no mechanical parts in the wastewater. The entire wastewater movement is carried out by non-clogging airlift pumps. Before the system discharges the clean water from the system, it flushes the airlift pipes with compressed air to clean them and remove any suspended solids that have settled in them. This ensures a very low level of suspended solids in the treated wastewater.

5. Clear Water Extraction

In this phase, the system drains the treated water from the system. The system completely discharges the clean water from the upper water column. The operator can use this for irrigation or discharge it underground into the environment.

- Lorem Ipsum

- Lorem Ipsum

- Lorem Ipsum

Lorem Ipsum

Advantages

- ✓ Guaranteed Compliance

Fully meets all agreed wastewater purification standards.

- ✓ Long-Term Warranty

Includes a 15-year warranty on selected parts for added peace of mind.

- ✓ Global Experience

Successfully installed in over 50 countries worldwide.

- ✓ Made in Germany

Manufactured entirely under strict quality controls at our headquarters in Bayreuth, Germany.

- ✓ Quality Construction

Single-piece, rotationally moulded tank reinforced with stainless steel for long-lasting performance.

- ✓ Aftersales Support

Dedicated aftersales customer support team on hand.

Videos

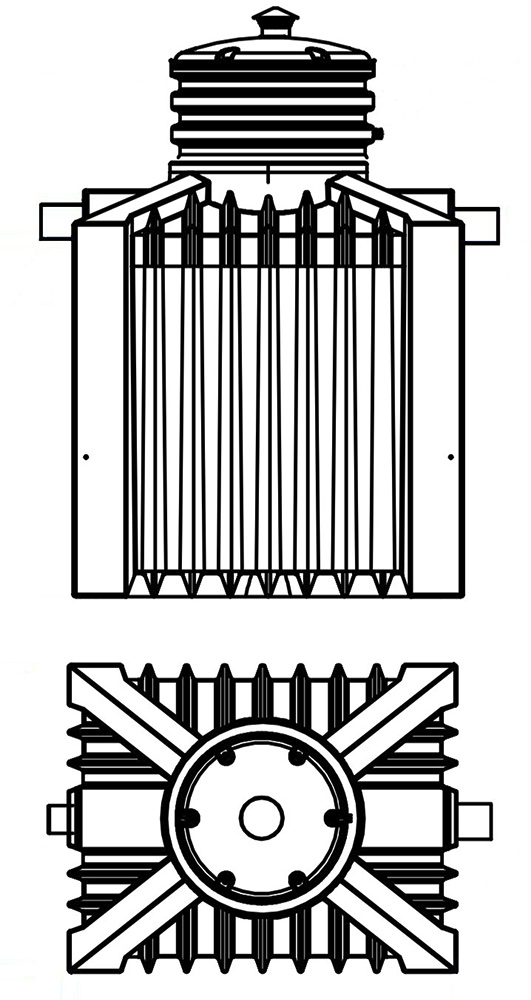

Specifications

| Power consumption | 0,52 kWh/day |

|---|---|

| Dimensions | Height: 220 cm Length: 153 cm Width: 122 cm |

| Capacity | 4 PE |

| Drainage class | N |

| Cleaning performance | COD: 93.7% BOD: 98.1% TN: 67.6% NH4-N: 99.4% SS: 95.8% |

| Effluent quality | COD: 48 mg/L BOD: 6 mg/L TN: 18 mg/L NH4-N: 0.2 mg/L SS: 17 mg/L |

| Degree of use | Direct discharge |

| Material | KG / PE |

| Downloads | Drawing |

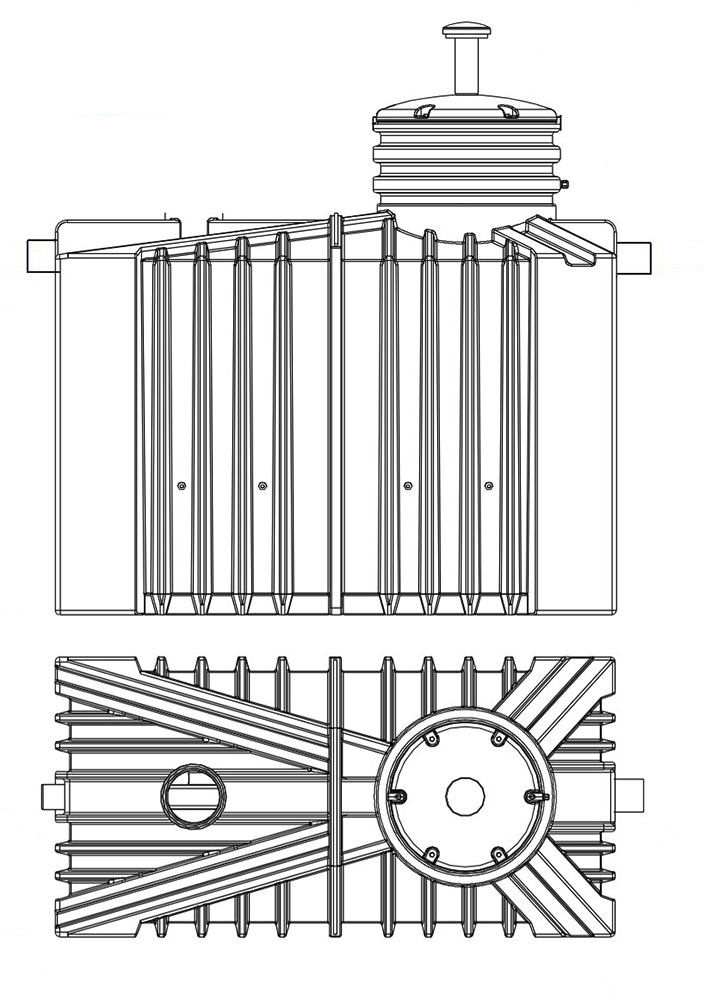

| Power consumption | 0,52 kWh/day |

|---|---|

| Dimensions | Height: 220 cm Length: 243 cm Width: 122 cm |

| Capacity | 6 PE |

| Drainage class | N |

| Cleaning performance | COD: 93.7% BOD: 98.1% TN: 67.6% NH4-N: 99.4% SS: 95.8% |

| Effluent quality | COD: 48 mg/L BOD: 6 mg/L TN: 18 mg/L NH4-N: 0.2 mg/L SS: 17 mg/L |

| Degree of use | Direct discharge |

| Material | KG / PE |

| Downloads | Drawing |

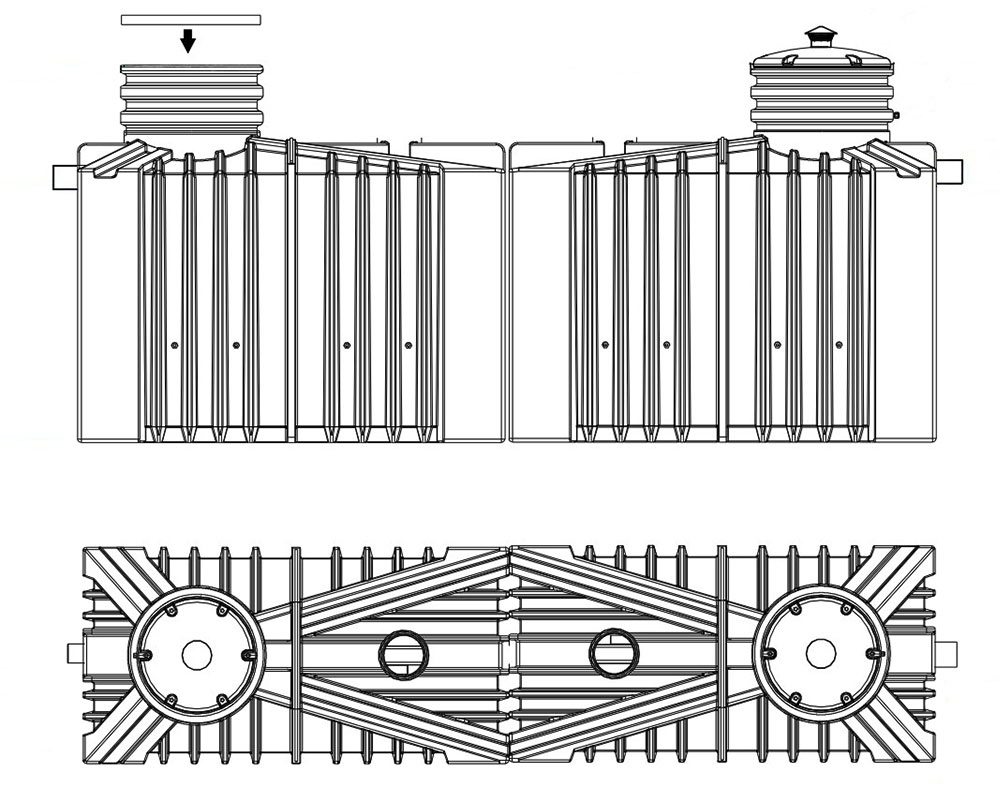

| Power consumption | 1,04 kWh/day |

|---|---|

| Dimensions | Height: 220 cm Length: 486 cm Width: 122 cm |

| Capacity | 12 PE |

| Drainage class | N |

| Cleaning performance | COD: 93.7% BOD: 98.1% TN: 67.6% NH4-N: 99.4% SS: 95.8% |

| Effluent quality | COD: 48 mg/L BOD: 6 mg/L TN: 18 mg/L NH4-N: 0.2 mg/L SS: 17 mg/L |

| Degree of use | Direct discharge |

| Material | KG / PE |

| Downloads | Drawing |

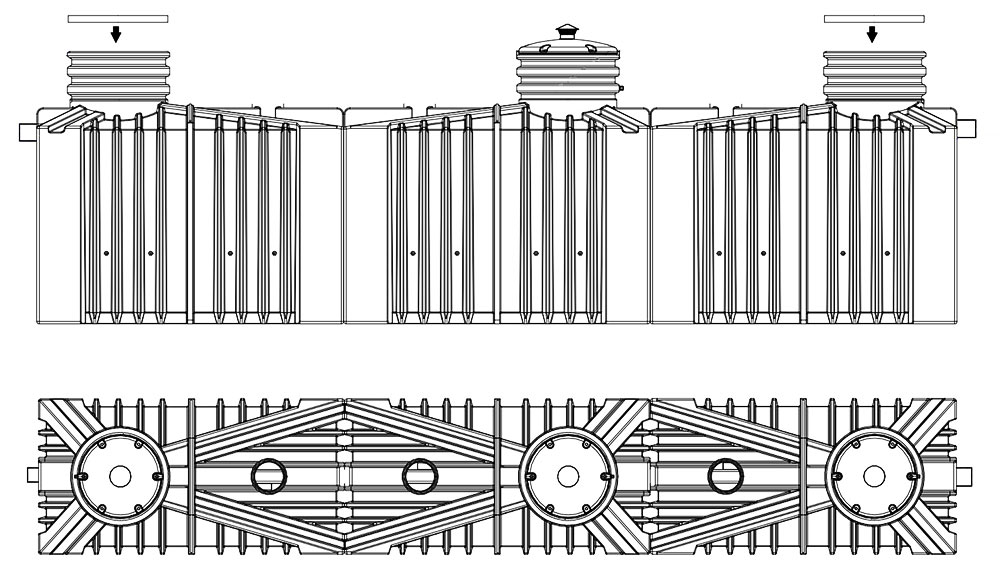

| Power consumption | 1,55 kWh/day |

|---|---|

| Dimensions | Height: 220 cm Length: 729 cm Width: 122 cm |

| Capacity | 18 PE |

| Drainage class | N |

| Cleaning performance | COD: 93.7% BOD: 98.1% TN: 67.6% NH4-N: 99.4% SS: 95.8% |

| Effluent quality | COD: 48 mg/L BOD: 6 mg/L TN: 18 mg/L NH4-N: 0.2 mg/L SS: 17 mg/L |

| Degree of use | Direct discharge |

| Material | KG / PE |

| Downloads | Drawing |

| Power consumption | 2,1 kWh/day |

|---|---|

| Dimensions | Height: 220 cm Length: 729 cm Width: 244 cm |

| Capacity | 24 PE |

| Drainage class | N |

| Cleaning performance | COD: 93.7% BOD: 98.1% TN: 67.6% NH4-N: 99.4% SS: 95.8% |

| Effluent quality | COD: 48 mg/L BOD: 6 mg/L TN: 18 mg/L NH4-N: 0.2 mg/L SS: 17 mg/L |

| Degree of use | Direct discharge |

| Material | KG / PE |

| Downloads | Drawing |

Downloads

Reference Projects

FAQs

1. What is the ClearFox® QuickOne+ system?

The ClearFox® QuickOne+ is a fully pre-assembled Sequencing Batch Reactor (SBR) domestic sewage treatment plant designed for applications ranging from 4 to 24 Population Equivalents (PE). Manufactured in Germany by PPU Umwelttechnik GmbH, it is suitable for new developments or as an upgrade to existing septic tank systems in residential, commercial, or domestic settings.

2. How does the ClearFox® QuickOne+ system work?

The system operates using an SBR process technology with fully aerated chambers. It features a smart SBR process that automatically adjusts aeration times based on inflow conditions. An integrated pressure sensor allows the system to increase oxygen supply during higher inflow peaks to enhance performance, and switch to standby mode during low inflow periods.

3. What are the key features of the ClearFox® QuickOne+ system?

- No Replacement Parts: Designed without components that require regular replacement.

- No Noise: Operates silently, ensuring no disturbance.

- No Odour: Engineered to prevent unpleasant smells.

- EN 12566-3 Certified: Meets European standards for small wastewater treatment systems.

4. Can the ClearFox® QuickOne+ system be installed in sensitive areas?

5. What is the desludging interval for the ClearFox® QuickOne+ system?

The system has been tested and proven to have desludging intervals of more than one year, reducing maintenance frequency and associated costs.

6. Is the ClearFox® QuickOne+ system suitable for upgrading existing septic tanks?

Yes, the ClearFox® Nature can be utilized to upgrade existing septic tanks, enhancing wastewater treatment efficiency without the need for electrical power.

7. What applications are suitable for the ClearFox® QuickOne+ system?

The system is versatile and can be used in various settings, including houses, schools, restaurants, and other commercial or domestic applications requiring efficient sewage treatment solutions.