Agricultural Wastewater Treatment

Sector Overview

Home > Agricultural Wastewater Treatment

Contents

Agricultural wastewater treatment is an important part of modern farm management. It addresses pollution control from various agricultural operations while enabling sustainable water resource management. Agricultural wastewater encompasses everything from livestock manure and dairy washings to crop processing effluents and irrigation runoff, each requiring different treatment approaches to meet strict environmental regulations.

The Impact of Agricultural Wastewater

Agricultural wastewater is defined as all wastewaters that have been used in agricultural operations and subsequently require treatment or disposal. This broad category encompasses both point source pollution from concentrated animal feeding operations and nonpoint source pollution from surface runoff that may be contaminated by various agricultural inputs.

The significance of agricultural wastewater management cannot be overstated, as agriculture accounts for a substantial proportion of diffuse pollution in many regions, making effective treatment systems essential for environmental protection.

The characteristics of agricultural wastewater vary significantly depending on the source, but common features include elevated levels of organic matter, nutrients such as nitrogen and phosphorus, suspended solids, and potentially pathogenic microorganisms. Unlike municipal or industrial wastewater, agricultural effluents often contain biodegradable organic compounds that can be effectively treated using biological processes, though some streams containing pesticide residues may require advanced treatment technologies.

The environmental impact of untreated agricultural wastewater extends far beyond the immediate farm environment. When these waste streams enter water bodies, they can cause eutrophication through excessive nutrient loading, leading to harmful algal blooms and oxygen depletion that threatens aquatic ecosystems. Additionally, groundwater contamination from agricultural runoff poses serious risks to drinking water supplies and long-term environmental health.

Sources and Composition of Agricultural Wastewater

Livestock operations represent one of the most significant sources of agricultural wastewater, with dairy farms alone contributing to more than 40% of animal wastewater according to many studies in Europe and the USA. These operations generate multiple waste streams, each with distinct characteristics requiring specific treatment approaches.

Concentrated Animal Feeding Operations (CAFOs) represent a significant source of pollution. In these situations, animals are kept housed in stalls and buildings, with the animal waste/slurry then being collected and stored in slurry pits/lagoons or tanks. In many situations this slurry is then spread on the land at certain periods during the year to act as a fertiliser. But increasingly due to stricter regulations regarding nitrogen and other pollutants in groundwater, this slurry spreading is becoming increasingly difficult. In such situations, multi step treatment processes to remove the nitrogen from this wastewater is necessary.

Food and agricultural processing facilities generate substantial volumes of wastewater with highly variable characteristics depending on the specific products and processes involved. These facilities typically require large amounts of water for cleaning, processing, and sanitation activities, resulting in effluents with high concentrations of organic contaminants.

Surface Runoff from agricultural fields represents a dispersed source of pollution, carrying animal wastes, fertilizers, pesticides, and sediment into nearby water bodies. The nitrogen content of cattle feedlot runoff varies significantly based on rainfall patterns and management conditions, ranging from 5 to 360 lb N/acre-inch depending on annual precipitation and facility design.

| Source Type | BOD₅ (mg/L) | COD (mg/L) | Total Nitrogen (mg/L) | Total Phosphorus (mg/L) | TSS (mg/L) | Volume (gallons/100 animals) |

|---|---|---|---|---|---|---|

| Dairy Milking Center | 400-10,000 | 4,997 | 80-900 | 25-170 | – | 73,000 |

| Silage Leachate | 12,000-90,000 | – | 4,400 | 500 | – | 105,000 |

| Barnyard Runoff | 1,000-10,000 | – | 50-2,500 | 5-500 | – | 80,000 |

| Dairy Manure | 20,000 | – | 5,600 | 900 | – | 660,000 |

| Food Processing | 700-2,000 | 1,000-3,500 | 100-350 | 30-100 | 350-700 | – |

| Fruit/Vegetable Processing | 500-5,000 | 1,030-5,630 | Low | Low | Variable | – |

Treatment Technologies for Agricultural Wastewater

There are a number of wastewater treatment technologies that can be employed for the treatment of agricultural wastewaters. Whether they are used as standalone processes, or combined as a multi step treatment solution depends specifically on the wastewater composition and the required cleaning standards. ClearFox manufactures a complete range of products and process technologies, so we are well positioned to provide solutions to agricultural wastewater treatment challenges.

Biological Treatment Systems

Biological treatment systems form the cornerstone of agricultural wastewater management, utilizing natural microorganisms to break down organic matter and remove nutrients effectively. These systems are particularly well-suited for agricultural applications due to the biodegradable nature of most agricultural waste streams.

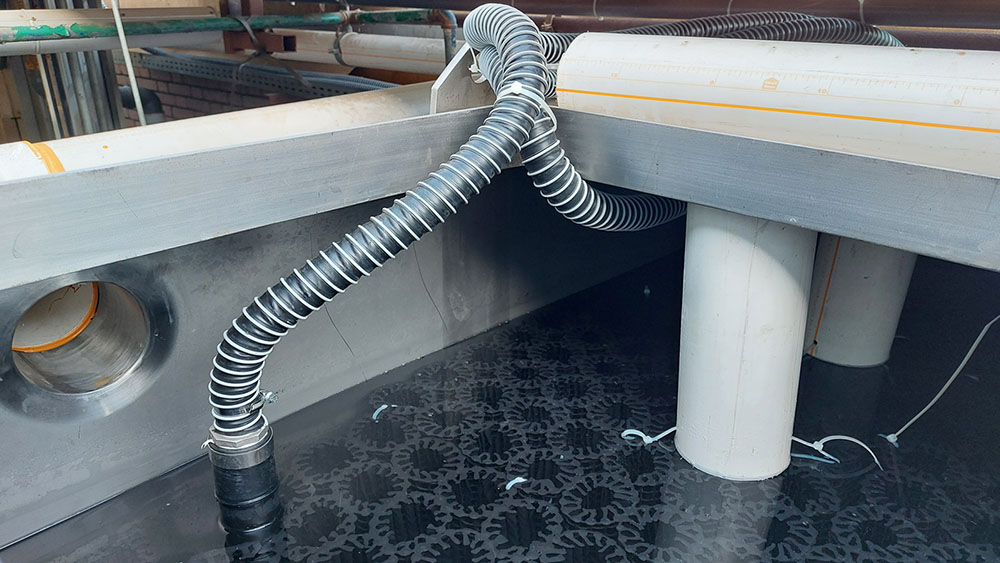

Fixed bed biological treatment represents one of the most effective biological treatment methods for agricultural wastewater. ClearFox modular fixed bed reactors have been implemented on many agricultural projects to treat slurry and contaminated runoff from farmyards. This process utilizes aeration and natural bacteria and protozoa to biologically oxidize organic pollutants. The fixed bed process is specifically designed to oxidize carbonaceous biological matter, remove nitrogenous compounds, and eliminate nutrients such as nitrogen and phosphorus. The system operates by mixing air or oxygen into wastewater in a fixed bed reactor, followed by separation and clarification in a settling tank where biological sludge settles and can be recycled back to the aeration process.

Dissolved Air Flotation (DAF) technology provides highly effective removal of biological solids from agricultural wastewater. DAF systems are specifically designed to reduce total suspended solids (TSS), biochemical oxygen demand (BOD), chemical oxygen demand [COD] and fats, oils, and greases (FOG) from wastewater streams. The process involves mixing air and pressurized water to form micro-bubbles that adhere to flocs of suspended material, creating a floating bed of sludge that can be easily removed. Dissolved air flotation can be used to remove the pollutant load or suspended solid load upstream of a biological treatment step as part of a multi stage treatment process.

Multi-Stage Treatment Systems combine multiple technologies to achieve comprehensive pollutant removal while maximizing resource recovery potential. ClearFox has implemented multi stage treatment processes including dissolved air flotation, biological treatment and clarifiers for the removal of nitrogen from the liquid phase of separated animal slurry.

Conclusion

Agricultural wastewater treatment represents a complex but essential component of sustainable farming operations, requiring sophisticated understanding of diverse waste stream characteristics and appropriate technology selection. The variety of agricultural wastewater sources, from livestock operations producing high-strength organic waste to crop processing facilities generating easily biodegradable effluents, demands flexible treatment approaches tailored to specific operational requirements and regulatory compliance needs.

Planning And Purchasing A Treatment Plant for Agricultural Slurry And Wastewater

At ClearFox, we understand that selecting the correct wastewater treatment process for your facility is crucial for ensuring regulatory compliance, environmental protection, and cost-effective operations. This guide will help you navigate the various factors to consider when choosing the best wastewater treatment solution for your business.

- Regulatory Compliance and Treatment Goals: It is essential to choose a treatment system that meets your local and federal regulatory requirements while effectively removing contaminants from your wastewater stream.

- Capital Expenditure (CAPEX): Investing in a wastewater treatment system involves various costs, including equipment purchase, installation, and civil works. Carefully evaluate the initial investment required for different treatment options and select one that offers the best value for money while meeting your treatment objectives.

- Operational Expenditure (OPEX): The ongoing operational costs of a treatment system include energy consumption, consumables, maintenance, and labour. Consider these factors when comparing treatment options to ensure that your choice offers both efficient performance and long-term cost savings.

- Available Space and Infrastructure: Space constraints within your facility can significantly impact the selection of a wastewater treatment system. Assess the available space and infrastructure for the installation and operation of the treatment system and choose a solution that fits seamlessly into your facility’s layout.

- Treatment Technologies and System Flexibility: wastewater streams can vary greatly in terms of pollutant concentrations and characteristics. Therefore, it is vital to choose a treatment system that can handle fluctuating wastewater characteristics and adapt to changes in production processes.

- System Efficiency and Reliability: A reliable and efficient wastewater treatment system will ensure consistent compliance with regulations and minimize the risk of environmental incidents. Evaluate the performance of various treatment options and their track record of success in similar applications.

- Ease of Maintenance and Support: Select a treatment system that requires minimal maintenance and comes with robust technical support from the manufacturer. Having access to reliable after-sales service and support is crucial for ensuring the long-term success of your wastewater treatment system.

Ready to Plan Your System?

Click below to access our quick guide on:

• Key design questions

• Common mistakes to avoid

• Factors that influence pricing

Up Next

Clearfox® Nitro | Digestate and Slurry Treatment Plant

Modern farming practice with increased stock per m², is a complex, dynamic and challenging business. The resulting slurry provides its own challenges

Slurry treatment with a ClearFox® treatment plant

ClearFox® slurry wastewater treatment plants do an excellent job of treating slurry, conserving the earth, requiring no transport and removing bad odours. Slurry treatment creates huge benefits for farmers. What is slurry? Slurry is a fertiliser produced from the faeces and urine of farm animals. The farmer differentiates between thick and thin slurry, depending on the bedding added. Slurry is valuable as a fertiliser. It contains: bound nitrogen Potassium nitrate sodium nitrite ammonium magnesium sulphate Phosphorus By using slurry, farmers can often do without synthetic fertiliser. However, in areas with intensive livestock farming, too much slurry is produced. This turns slurry into waste, and in many cases the respective counties have not yet sufficiently regulated the disposal and recycling procedures. If farmers spread their slurry excessively and outside the growing season, there is a risk of contaminating the groundwater near the surface with nitrate. Fine dust is also formed by slurry. Different types of slurry Most slurry is produced

- 40,000+ treatment systems

- Installed in over 50 countries

- Treating 25 million litres daily

- Certified.

- Compact.

- Containerized.

- [Clever.]