Oil And Gas Wastewater Treatment

Sector Overview

Home > Oil And Gas Wastewater Treatment

Contents

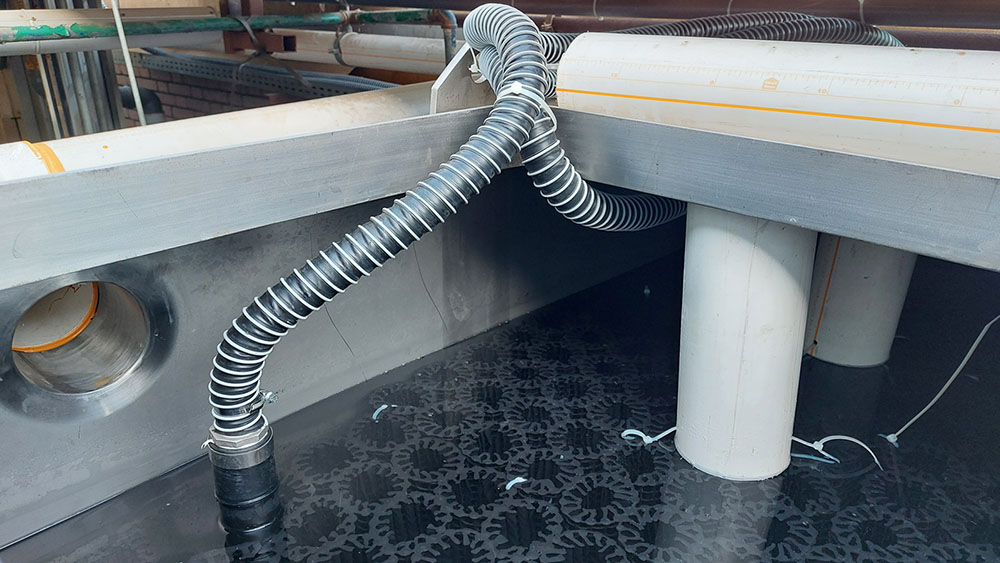

The oil and gas industry generates significant amounts of wastewater from upstream and downstream activities which must be managed. Produced water and other wastewater sources need to be cleaned and treated before release into the environment as they can be highly polluted. ClearFox® has developed a range of modular solutions to treat produced water.

The Oil And Gas Sector

The oil and gas sector is listed among the top ten largest water consumers and causes significant water pollution. The industry is faced with higher standards for environmental protection and due to the current global market, lower prices. The environmental situation is exacerbated by a lack of water at most drilling sites. At many locations, the wastewater is not adequately treated to comply with local legislation. Wastewater treatment of produced water in oil fields is now considered to be a priority.

The wastewater on oil and gas well fields can be contaminated in different ways. We use our approved-and-tested module system and select the technology used with an evaluation procedure that is always tailored to the specific requirement.

With our modular system, we have experience worldwide in cleaning a wide variety of wastewater types. We are members of the leading professional associations in Germany:

VDE – Association German Technologies Electrical, electronical and information

VDI – Association German Engineers

ATV/DWA – German Wastewater Association

Wastewater Characteristics: Oil And Gas Industry

The wastewater from the oil and gas sector is highly variable in its volume and pollution load. This depends on many factors so in each case a specific solution must be designed. By utilising our modular process technologies, we can adapt modules to handle any flowrate, any pollution loading and any effluent requirement. Characteristics of produced wastewater are described below; The usual parameters for assessing the water quality or the efficiency of the treatment technology are as follows: (different analyses from Siberia, USA, South America and Mediterranean Sea)pH 4-7

Oil content can be up to 1 g/l but is mostly removed from the produced water (as it is the valuable substance)

Salt concentration (salinity): The salinity is a typical characteristic of the produced wastewater. It can contain over 180,000 mg/l. This can usually be seen from the TDS, which essentially consists of sodium chloride. The chloride content is also an important indicator. Much produced wastewater is considered hypersaline, i.e. oversaturated with salt.

Total dissolved solids (TDS) up to 300,000 mg/l, mainly caused from NaCl

Total suspended solids (TSS) between 50 and 1,000 mg/l

Temperature 15 to 35 degree Celsius regionally dependent

Hydrocarbons (aliphatic and aromatic)

Volatile, aromatic hydrocarbons BTEX (sum of Benzene, Toluene, Ethylbenzene and Xylene)

Polycyclic, aromatic hydrocarbons PAH (PAH and alkyl phenols are not very good soluble in the wastewater.)

Organic acids such as Benzoic acids

Dispersed hydrocarbons, naphtha residues

- Sum parameter for oxygen demand (chemical oxygen demand COD, biological oxygen demand BOD, usually determined in 5 days). The ratio of these two typical sum parameters gives an indication of the degradability of wastewater. BOD values vary from 500 to 3,000 mg/l, COD values vary from 2,000 to 20,000 mg/l

Nitrogen, Phosphorus (only seen as traces in relation to carbon, but may contain an excess of nitrogen, which must be removed for some direct discharges)

Sulfides, depending on injection water

Heavy metals (Boron, Cadmium, Copper, Mercury, Iron and much more)

Radioactive materials (NORM, technically enhanced), uranium, thorium, radium with his decay products as well as radon Lead 210, potassium 40, polonium (Partially gaseous, especially concentrated in the sludge and deposits, loads of up to 15,000 Becquerel/gram, average waste load 100 Bq/g)

Planning And Purchasing A Wastewater Treatment Plant for Petrochemical Applications

| Wastewater Type | Source | Key Characteristics | Major Contaminants | Treatment Methods |

|---|---|---|---|---|

| Produced Water | Onshore/Offshore | Formation water extracted with hydrocarbons; high salinity (Cl⁻ up to 300,000 mg/L). | Hydrocarbons, sulfides, NORM (Ra-226/228), BTEX, dissolved metals (Ba, Sr). | Offshore: DAF (≤29 mg/L oil). Onshore: Reinjection (80%), evaporative concentration. |

| Flowback Water | Onshore (Fracking) | Fracturing fluid returns (20–40% injected volume); TDS: 50,000–300,000 mg/L. | Proppants, guar gum, biocides (≤500 mg/L), BTEX, PAHs. | Reuse (50–70%), RO membranes, electrocoagulation, constructed wetlands. |

| Spent Caustic | Refineries | Alkaline wastewater from Merox units, scrubbing LPG/gasoline; pH 11–14. | Sulfides (0.5–8% S), mercaptans, phenols (≤2,000 ppm), naphthenic acids (≤15%). | Wet air oxidation (WAO), catalytic oxidation, acid neutralization (CO₂ injection). |

| Sour Water | Refineries | Condensed steam from stripping units; high H₂S/NH₃ content. | H₂S (≤5,000 ppm), NH₃ (≤10,000 ppm), phenols, cyanides. | Steam stripping, biological treatment, chemical oxidation (H₂O₂). |

| Desalter Effluent | Refineries | Brine from crude oil washing; high TSS and salinity. | Salts (NaCl, CaCl₂), metals (Fe, Ni), emulsified oil, amines. | Pretreatment (DAF), solids settling, reverse osmosis. |

| Hydrotest Water | Onshore/Offshore | Pipeline pressure testing water; low organic content. | Oxygen scavengers (hydrazine), biocides (gluteraldehyde), chlorides (<50 ppm). | Filtration, chlorination, pH adjustment (>10) for reuse. |

| API Separator Effluent | Refineries | Primary treated wastewater after oil/water separation; residual emulsified oil. | TPH (≤100 mg/L), TSS (≤200 mg/L), benzene, toluene. | Secondary DAF, biological reactors, multimedia filtration. |

| Cooling Tower Blowdown | Refineries/Offshore | High TDS from recirculating cooling systems; elevated temperature. | Scaling ions (Ca²⁺, Mg²⁺), corrosion inhibitors (phosphate), biocides. | Softening, ion exchange, evaporation ponds. |

| Sanitary Wastewater | Both | Domestic sewage from crew facilities; moderate organic load. | BOD₅ (250–400 mg/L), TSS (200–350 mg/L), coliforms, detergents. | Compact bioreactors (offshore), activated sludge (onshore). |

| Deck Drainage | Offshore | Rainwater/cleaning runoff from platforms; intermittent flow. | Free oil (50–200 mg/L), corrosion inhibitors (imidazolines), grease. | API oil-water separators, hydrocyclones (≤15 mg/L monthly avg). |

At ClearFox, we understand that selecting the correct wastewater treatment process for your facility is crucial for ensuring regulatory compliance, environmental protection, and cost-effective operations. This guide will help you navigate the various factors to consider when choosing the best wastewater treatment solution for your business.

- Regulatory Compliance and Treatment Goals: It is essential to choose a treatment system that meets your local and federal regulatory requirements while effectively removing contaminants from your wastewater stream.

- Capital Expenditure (CAPEX): Investing in a wastewater treatment system involves various costs, including equipment purchase, installation, and civil works. Carefully evaluate the initial investment required for different treatment options and select one that offers the best value for money while meeting your treatment objectives.

- Operational Expenditure (OPEX): The ongoing operational costs of a treatment system include energy consumption, consumables, maintenance, and labour. Consider these factors when comparing treatment options to ensure that your choice offers both efficient performance and long-term cost savings.

- Available Space and Infrastructure: Space constraints within your facility can significantly impact the selection of a wastewater treatment system. Assess the available space and infrastructure for the installation and operation of the treatment system and choose a solution that fits seamlessly into your facility’s layout.

- Treatment Technologies and System Flexibility: wastewater streams can vary greatly in terms of pollutant concentrations and characteristics. Therefore, it is vital to choose a treatment system that can handle fluctuating wastewater characteristics and adapt to changes in production processes.

- System Efficiency and Reliability: A reliable and efficient wastewater treatment system will ensure consistent compliance with regulations and minimize the risk of environmental incidents. Evaluate the performance of various treatment options and their track record of success in similar applications.

- Ease of Maintenance and Support: Select a treatment system that requires minimal maintenance and comes with robust technical support from the manufacturer. Having access to reliable after-sales service and support is crucial for ensuring the long-term success of your wastewater treatment system.

Ready to Plan Your System?

Click below to access our quick guide on:

• Key design questions

• Common mistakes to avoid

• Factors that influence pricing

Share:

Up Next

Pharmaceutical wastewater treatment process

This comprehensive guide explores the sources, composition, and types of wastewater generated by pharmaceutical and cosmetic companies, with an emphasis on major pollutants and a detailed breakdown of APIs.

Design of a pharmaceutical wastewater treatment plant

This text is tailored for those with a deep understanding of pharmaceutical and cosmetic wastewater composition, seeking detailed knowledge of available treatment technologies and processes.